Linde LT16 Ch - BMh

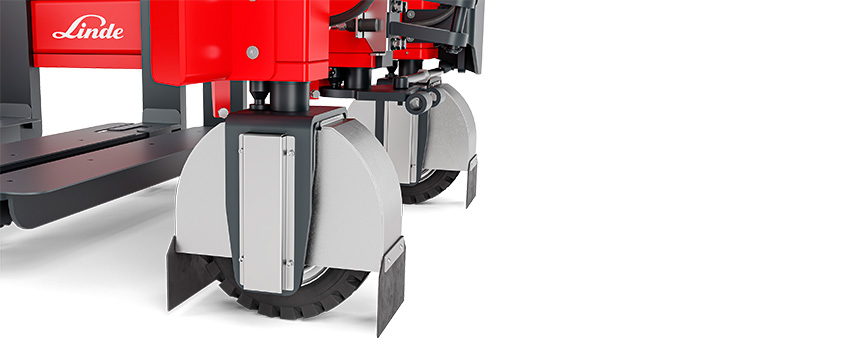

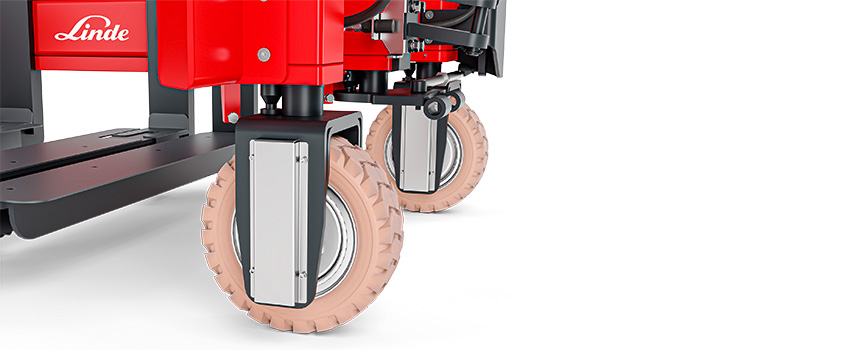

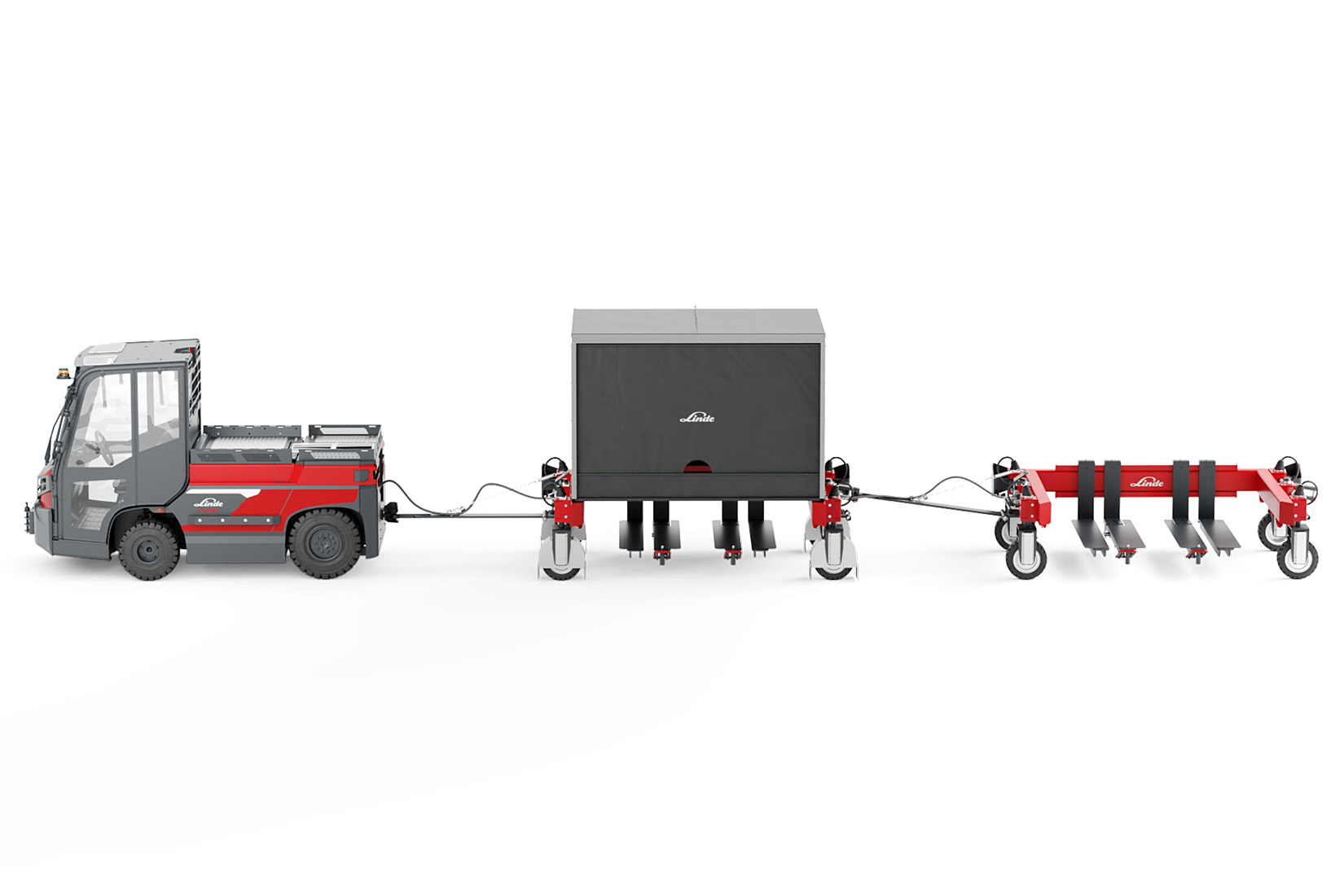

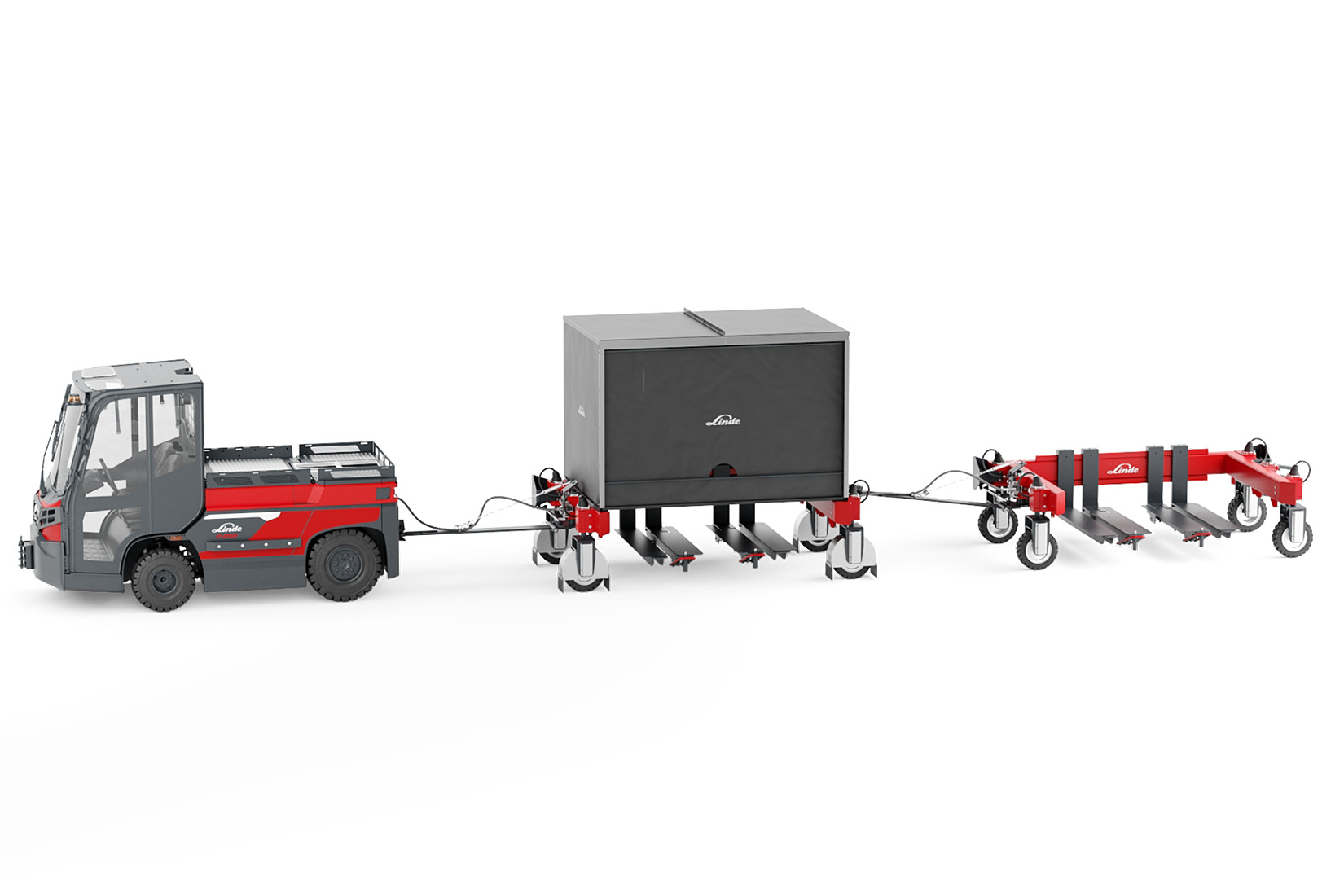

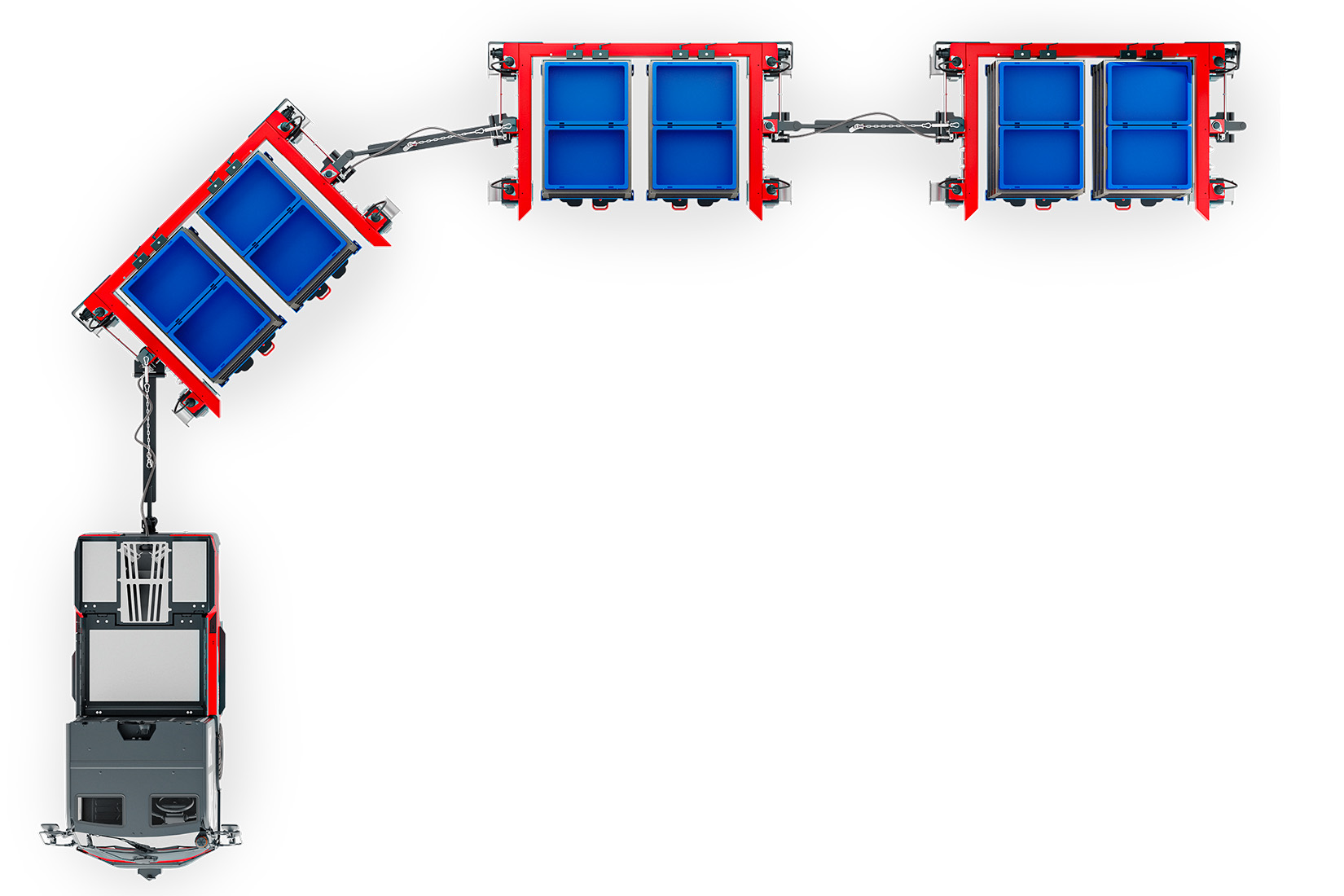

Logistic Trains LT16 Ch/BMh

Heavy-duty Outdoor Logistic Train