The next auction starts on Tuesday, January 20th. and ends on Thursday, January 22nd., 2026 - Visit online auction

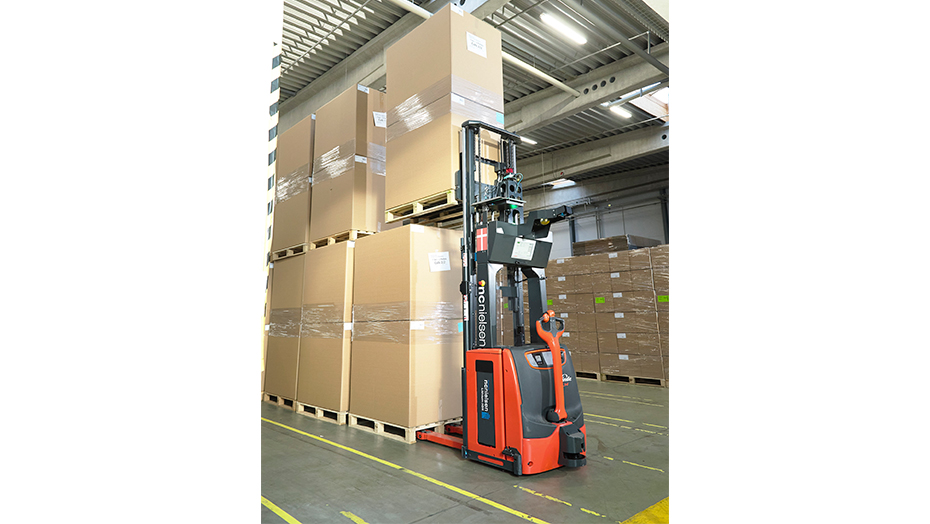

The AGV solution at DAFA features an entirely new generation of AGV technology. It consists of a Linde L14 stacker with state-of-the-art navigation and safety features enabling it to run long distances, up and down ramps, around corners, through various rack aisles and into well-defined pick-up and delivery zones.

The AGV machine has been named Agnes and basically runs round-the-clock from the production to the warehouse and from the goods reception to the warehouse. It picks up pallets at 14 different stations, carries 120 cm wide disposable pallets and handles more than 8,000 tasks a year. The AGV machine reacts quickly, for example if splinters or film gets in the way - and obviously also stops when registering persons or other machines on its route.

- We used to have a different AGV solution which did not boast the same features. The new AGV solution from N.C. Nielsen is a technological advance featuring many new functions. For example, it can do block stacking more than four metres high, map the rooms dynamically during operation and automatically go to the charging station for charging where the Lithium-ION battery will be fully charged in a matter of a few minutes. We see great potential in the AGV technology, says Jesper Holm Rasmussen, Warehouse Manager, DAFA.

It was crucial to DAFA that the AGV solution would contribute to widely different transport tasks. DAFA’s internal logistics flow was analysed in detail, the physical rooms with more than 5,000 pallet places were mapped, the development potential was assessed - and obviously, the combined economy linked to the AGV solution was also an important factor.

- According to our calculations, the AGV solution will be repaid in two years. We consider it a good investment which will help us through a growth period without hiring more people. At the same time, the AGV solution has taken over the most tedious logistics tasks so that our employees can now focus on more varied picking and packaging tasks. The AGV solution was well received and is part of the ordinary workflow, says Jesper Holm Rasmussen, Warehouse Manager, DAFA.

The AGV solution was delivered in a matter of seven weeks in 2019. N.C. Nielsen and Linde are already partners, and DAFA has a large fleet of Linde forklifts and stackers. Asking if N.C. Nielsen AGV would contribute to the task was therefore a natural step for DAFA. The answer was positive, and words are quickly carried into effect in Balling:

- Developing an AGV solution for DAFA was very exciting. They were very much ready to proceed to the next level within the AGV area. We worked out a technologically highly advanced solution which is able to do many things at the same time. Because of the complexity, we spend a lot of time and energy implementing, adjusting and fine-tuning. DAFA’s AGV solution now works perfect and is fully functional, says Henrik Gram Nielsen, Product Manager, N.C. Nielsen.

Would you like to know more?

Contact Sales Director Allan Christensen for more information