- We’re ready to handle all kinds of goods and are a logistical connecting link in global supply lines. When air planes arrive at the terminal, things go fast, and we only have little time to unload or load the cargo compartment. It takes good employees, a powerful fleet of forklift trucks, tractors and stackers as well as IT systems to monitor handling, says Peter Kehler Krabbe, Warehouse and Ramp Manager, WFS.

Linde at WFS

At European level, the WFS group has decided for all stations to use Linde equipment. At the terminal in Copenhagen, 32 Linde machines operate divided between Linde stackers for pallet cargo, Linde electric tractors to tow carts with airline pallets and Linde forklift trucks with fork clamps and forklift trucks with non-marking pneumatic tyres for the temperature-controlled pharmaceutical warehouse.

Efficient “parenting”

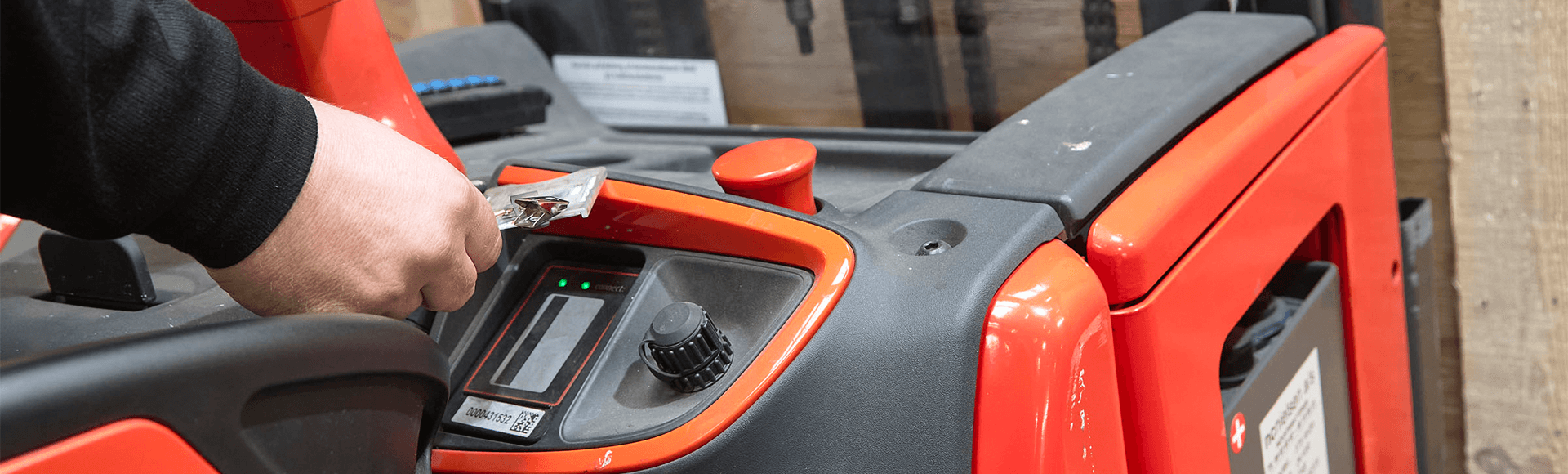

WFS uses Linde Connect to record all shock impacts on all machines, be it due to driving on uneven surfaces, collisions with racks or pallets or lost goods. Each operator registers using his or her card when starting, and shock impacts are therefore linked to named persons who are therefore encouraged to drive more responsibly.

- There definitely is a parenting element in the system. Our operators must drive responsibly, look out for each other and reduce the number of collisions. If there are five shock impacts a week, we’ll talk to the operator to correct the situation. We might be slightly annoying in that area, but it does in fact help, says Peter Kehler Krabbe, Warehouse and Ramp Manager, WFS.

Safe operation

Safety is another important aspect of the Linde Connect system. WFS machines are not allowed to run more than 12 km/h at WFS, and that is the case for all stations around the world. The exception to this rule is that Linde machines may drive faster in the outdoor environment, for example when a Linde tractor with goods carts is headed to the airside to reach the waiting air plane sooner.

Cooperation between WFS and N.C. Nielsen is regularly expanded in line with new transport needs and by virtue of continuous maintenance of the machine fleet. Linde Connect is continuously updated, and N.C. Nielsen is ready to educate within features, support and technical assistance to constantly keep the Linde Connect solution functional.

- The vision will have to be in place in order for Linde Connect to be fully utilised. There are plenty of opportunities to measure by collisions, speeds, the duration of the lifting operation and the lifting-driving time. An increasing number of Linde machines are “born” with a Linde Connect modem, but all machines can have it retrofitted and then integrated into the company's other IT system, says Bruno Mærsk Knudsen, Technical Supporter, N.C. Nielsen.