The next auction starts on Tuesday, January 20th. and ends on Thursday, January 22nd., 2026 - Visit online auction

DB Cargo Scandinavia operates the terminal, which is the largest of its kind in Denmark. It is centrally located in relation to the Scandinavian rail network, motorway system and the deep-water port of Fredericia. The terminal covers an area of 130,000 m², has three terminal tracks of 1,355 metres and a fleet that includes shunting locomotives, a terminal tractor and the two Konecranes reach stackers – the backbone of the terminal operations.

– “We’re seeing growing customer demand for transport solutions that reduce environmental impact, especially for long distances and fixed route services. In this context, we see ourselves as a vital link in the transport chain where terminal operations and efficient connections support more flexible freight transport – while remaining cost-effective,” says Team Leader Brian Hjortkjær from Taulov Kombiterminal.

Sustainability on track

With Flow Drive technology in the reach stackers, the terminal can now offer stronger sustainability arguments to its customers. Initial results show that the machines deliver significant CO₂ savings through reduced diesel consumption – helping lower the overall environmental impact. This aligns well with Taulov Kombiterminal’s ongoing focus on efficiency and green transition:

– “We depend on customer satisfaction. We must constantly adapt and make smart choices that reflect the market and meet customer expectations. We’re convinced that the new Konecranes reach stackers move us further along the green path. We have the advantage of being able to document the environmental improvements in our operations,” adds Brian Hjortkjær.

Measurable environmental benefit

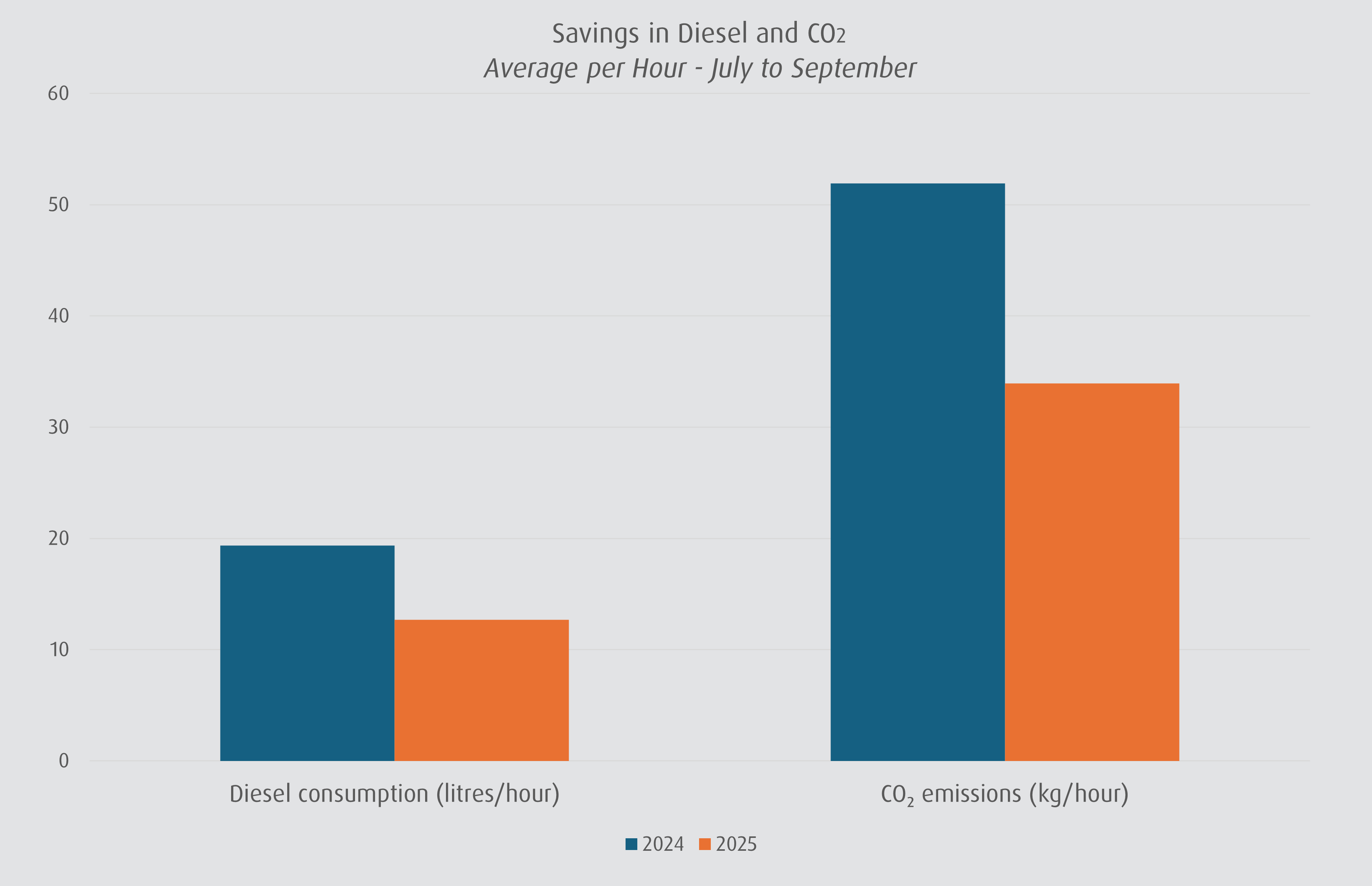

The two new Konecranes reach stackers arrived at Taulov Kombiterminal in May 2025. Environmental benefits were quickly confirmed through data from the built-in Konecranes Truconnect software. On average, the machines save 6.7 litres of diesel per hour, equivalent to a CO₂ reduction of 18.0 kg per machine per hour. This represents a 34.4% fuel saving and a 34.6% CO₂ reduction compared to the previous solution.

– “We can already document that the new Konecranes reach stackers are making a green difference at our terminal. It’s actually the combination of the Flow Drive technology and our drivers’ driving style that has improved the numbers. Our operators completed special training to learn how driving technique can maximise the machine’s potential,” says Brian Hjortkjær.

Flow Drive technology

A Konecranes reach stacker with Flow Drive technology features a Hydromechanical Variable Transmission (HVT) – an advanced system that combines hydrostatic and mechanical transmission for stepless speed control, fuel efficiency, and high performance in these heavy-duty machines.

The stepless transmission enables smooth and continuous acceleration. The hydrostatic part handles speeds from 0–6 km/h, after which the system switches to mechanical transmission with two additional gears. This allows the machine to move slowly – often without braking – when containers or trailers need to be loaded or unloaded onto rail wagons.

Improved driver comfort

The two Konecranes reach stackers operate year-round, from morning to evening. Four dedicated drivers and a pool of 16 multi-skilled staff with truck licences operate the machines. The trucks offer quiet operation, spacious cabins, suspension seats, camera-connected screens and modern IT systems for handling containers, trailers and swap bodies.

Konecranes tested the noise levels of the new machines according to standard protocols, measuring around a 16-metre radius during idle, driving and lifting. The machines achieved a noise reduction of 5 dB(A) during driving and lifting – a noticeable and significant reduction, equivalent to halving the perceived disturbing noise.

|

2024 measurements (Konecranes SMV 4636 TC6) Driving: 77 dB (A) 2025 measurements (Konecranes SMV 4532 TC5 HVT) Driving: 72,5 dB (A) Source: Konecranes |

|

Operators use a joystick and a mini-wheel, both positioned on the seat’s armrest, to control the lifting and driving. The joystick handles the lifting unit, while the mini-wheel manages driving. This setup improves ergonomics, reduces strain on shoulders, elbows and wrists, and provides better visibility of the load.

– “Our drivers really appreciate the improved operator comfort. The Flow Drive technology supports a quiet, smooth, and vibration-free driving experience. The driver has a wide field of view from an elevated position, can adjust the cabin laterally and enjoys optimal safety,” concludes Brian Hjortkjær from Taulov Kombiterminal.

Would you like to know more?

-

Claus Lilleholt CEO - N.C. Nielsen AB and N.C. Nielsen AS

Claus Lilleholt CEO - N.C. Nielsen AB and N.C. Nielsen AS -

-

Daniel Susgaard Sales - HEAVY Handling MACHINES & EQUIPMENT

Daniel Susgaard Sales - HEAVY Handling MACHINES & EQUIPMENT