The next auction starts on Tuesday, January 20th. and ends on Thursday, January 22nd., 2026 - Visit online auction

The model represents the next step in the green transition of heavy-duty transport and combines Terberg’s legendary robustness with modern EV technology.

A healthier and safer work environment

With the Terberg RT253EV, diesel fumes, particles, and exhaust gases are completely removed from the work area. This improves the health and safety of drivers, colleagues, and passengers – both on the quay and inside the ship. At the same time, noise and vibrations are significantly reduced, creating a more comfortable and productive working environment.

“It makes a huge difference to be able to work without noise and exhaust on the ship,” says one of the Scandinavian test customers. "The tractor is incredibly smooth, has strong traction, and a cabin that feels like a modern driver’s cab.”

Powerful and reliable electric driveline

At the heart of the RT253EV is the advanced ZF CeTrax asynchronous electric motor, delivering 250 kW peak power (170 kW continuous) and high torque. Together with 4x4 drive, the tractor gains solid traction and superior control when moving trailers weighing 30–60 tons GCW, even under slippery or steep conditions.

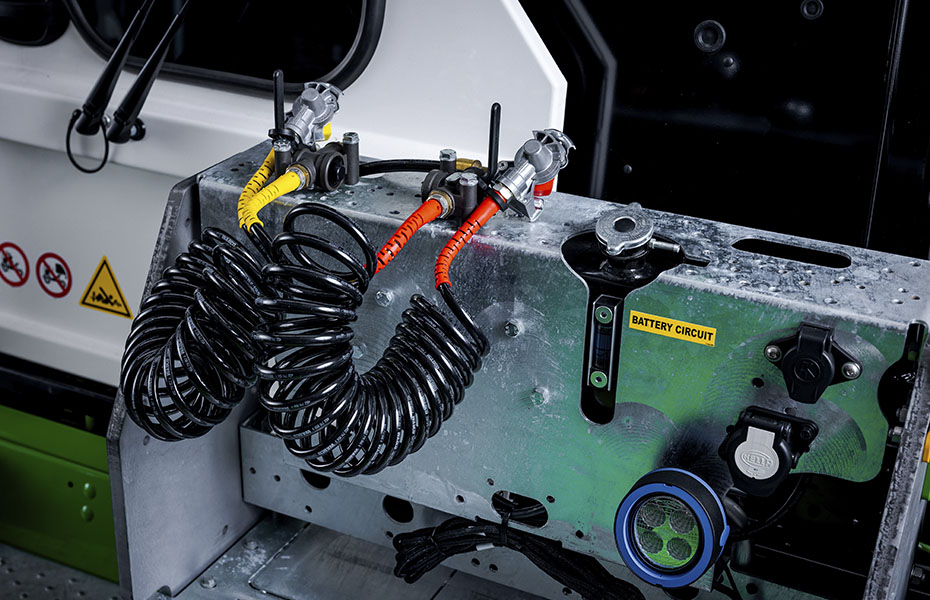

The newly developed driveline is optimised for RoRo operations, where frequent coupling and uncoupling require high precision. The RT253EV excels by automatically adjusting torque and braking force so that driving feels natural and stable regardless of load.

OPERATOR ENVIRONMENT IN FOCUS WITH MODERN FORKLIFTS

The Terberg RT253EV is available with two or three battery modules of 100 kWh each, equipped with a Thermal Management System (TMS) that provides efficient temperature control in both cold and warm climates. With up to 300 kWh of battery capacity, the range is more than sufficient for an entire workday.

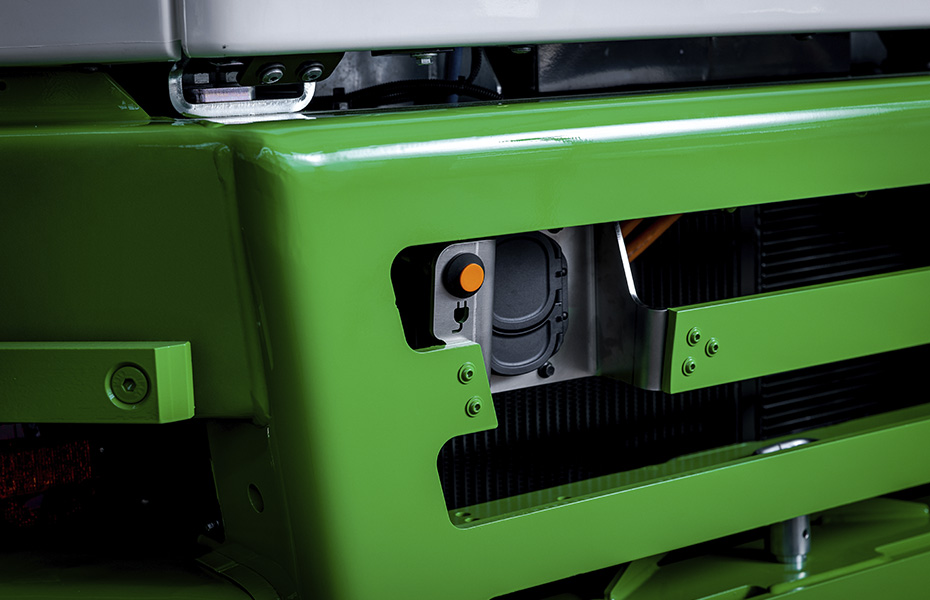

Via CCS2 fast charging, the battery can be charged from 20 to 80 percent in about 1 hour and 5 minutes (150 kW). This allows for flexible charging during breaks and ensures high availability for continuous operation around the clock.

Proven technology and robust construction

The RT253EV is built on Terberg’s third-generation EV platform, which has already proven its worth in the YT203EV and BC203EV. The driveline, software, and control systems are tried and tested and have been further developed specifically for RoRo applications.

At the same time, the chassis and frame are based on Terberg’s proven design, which for decades has set the standard for durability and serviceability in terminals worldwide. And should operational challenges arise, N.C. Nielsen’s efficient service organisation is ready to provide rapid response and competent maintenance throughout the Nordic region.

Comfort, ergonomics, and visibility in a class of their own

The RT253EV cabin has been developed with the driver’s comfort and safety at its core:

- Low noise and vibration levels thanks to special rubber mounts

- Efficient cabin filtration and climate control for a healthy environment

- Ergoturn® 180° rotating driver’s station, where the seat, steering wheel, pedals, and instruments rotate as one unit

- Air-suspended seat and ergonomically positioned controls

- Excellent visibility in both directions

The result is a cabin that feels spacious, intuitive, and comfortable – even during long working days.

Positive feedback from the demo tour

During the international demo tour in the United Kingdom, Scandinavia, and the Benelux countries, the RT253EV received overwhelmingly positive feedback from both drivers and operating personnel:

- “A very comfortable and quiet driving experience – the drivers didn’t want to get out again.”

- “We were impressed by the pulling power and how quiet it is on board. A clear improvement in the working environment.”

- “It drives like a diesel, with smooth acceleration, strong traction, and easy handling.”

Ready for green RoRo operation

With its combination of powerful performance, robust design, optimal range, and low operating costs, the RT253EV is the obvious choice for ports, ferries, and industrial companies wishing to electrify their RoRo operations without compromise.

Fully electric. Robust. Efficient. Future-proof.

Would you like to know more?

-

Claus Lilleholt CEO - N.C. Nielsen AB and N.C. Nielsen AS

Claus Lilleholt CEO - N.C. Nielsen AB and N.C. Nielsen AS -