Our box-type chassis is the strongest on the market. It is made of four welded steel plates as a closed box section. Compared to a conventional lift truck chassis, it features double torsional stiffness and higher strength, fewer stresses and strains, higher lifting capacity with no reductions at high lift heights, and strong tilt fixtures in both the chassis and mast.

Efficient load-sensing hydraulics

Our trucks come with hydraulics that can sense the load and adapt the lifting power to the weight of the load. The lift truck provides maximum power only when really needed, consuming less fuel while reducing emissions and noise. Service intervals are longer (4000 – 12 000h). There is less wear and tear on components. It all contributes to a lower total cost of ownership.

Intelligent Electronic Machine Control (EMC)

Our Electronic Machine Control system, EMC Master, monitors the lift truck's vital components and functions. Its settings are programmable to adjust to your needs. It can be linked with Konecranes' TRUCONNECT remote data monitoring and reporting system. CanBus technology increases engine and transmission reliability.

Auto start-stop

The auto start-stop feature turns off the engine whenever the truck idles for a prolonged period of time and restarts it automatically when needed. The working principle is simple. When the engine doesn't run, it doesn't consume fuel. Auto start-stop turns off the engine when it isn't needed: when the truck is idling, put it into neutral and take your foot off the brake to activate the function. "Start-stop" then appears on the info display and the engine shuts off. To restart the engine, put the truck into gear. When you press the brake, the engine starts again. If the truck is stationary but power is needed for lifting, touching the lifting lever or joystick will re-start the engine. This feature significantly reduces fuel consumption and CO2 emissions. It also lengthens the engine maintenance interval.

Don't choose between being green and being great

We want to empower you and your business to make better choices for the environment without compromising performance.So we give you the opportunity to save money and help the environment at the same time by using less fossil fuels – making everyone happier. ECOLIFTING is a future-proof concept with new solutions continuously in development. Like in all of our products, the true value lies in the small and intelligent details and cutting-edge technology that make Konecranes Lift Trucks some of the world’s most advanced lift trucks. Small things make a huge difference.

ECOLIFTING-løsninger:

Currently, Konecranes has three ECOLIFTING solutions available: Power Drive, with up to 15% fuel savings; Flow Drive, with up to 25% fuel savings; and the innovation we are most proud of – the Hybrid Drive, with up to 40% fuel savings.

Pick the fuel saving solution that fits your world the best and make choices for a better tomorrow.

Mere intelligent drift

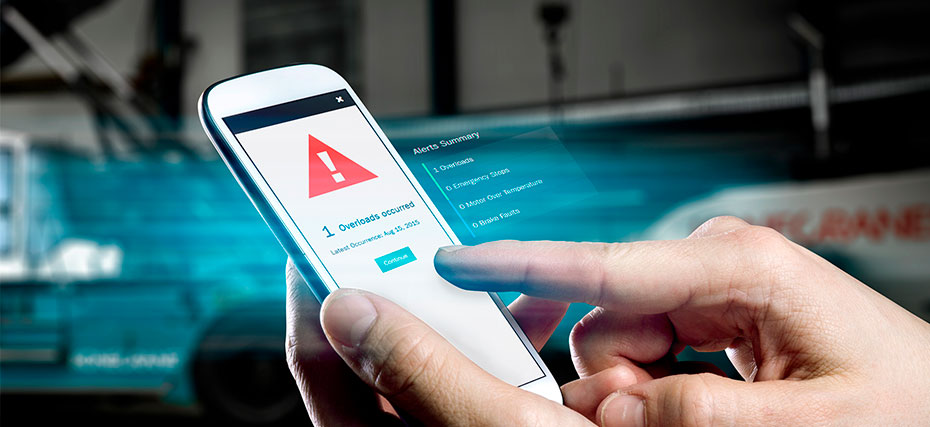

The world is changing faster than we expect, so we know that you need to keep up to meet your goals and stay ahead in the market. We are all working with limited time. At Konecranes, we want our Smart Connected Lift Trucks to empower you and your company to make the smartest decisions quickly in a digital era.

We offer a range of digital solutions such as TRUCONNECT®, preventive maintenance and mobile apps, that can help you manage your assets more efficiently, reduce costs, increase safety, reduce CO2 and increase productivity.

Want to learn more about KONECRANES?

Our experts at Konecranes are ready to help you with the solution that suits your needs.

-

Henrik Fischer Technical manager after sales

Henrik Fischer Technical manager after sales -

N.C. Nielsen Call-centerTlf. +45 99 83 83 83

N.C. Nielsen Call-centerTlf. +45 99 83 83 83