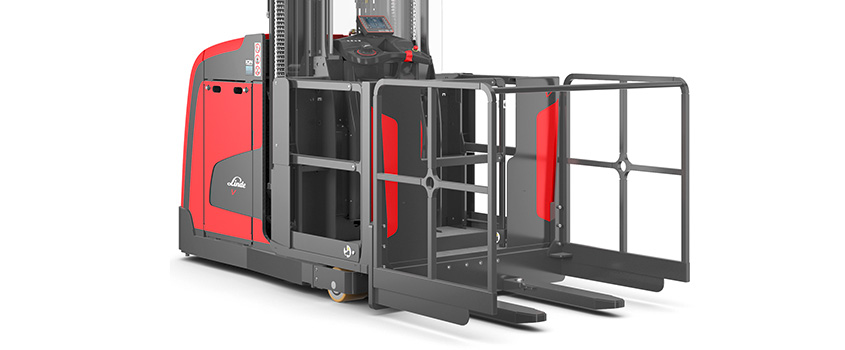

Linde V modular

Capacity: 1.200 kg.

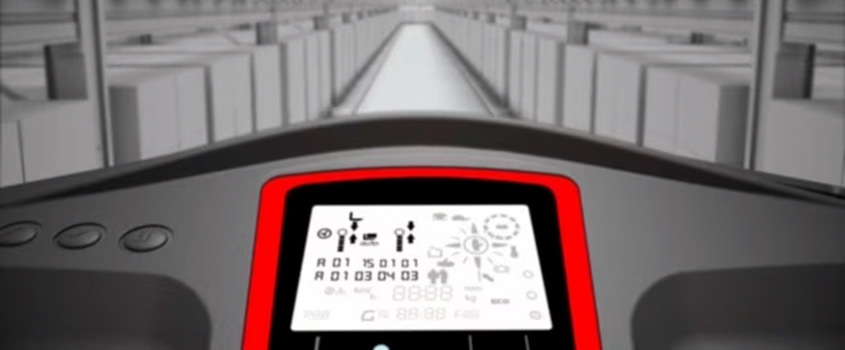

The V-modular order picker achieves pick heights of 14.5 meters and a capacity of 1200 kg. It features a vibration-damped driver's seat, ergonomic railing height, and ensures a high picking frequency. Two-handed operation enhances safety. Its ergonomic design, multi-function color screen, and innovative control concept make it efficient. The design is optimized for easy service.